Thermal management is a critical engineering consideration for any commercial battery storage system, directly influencing its performance and durability. For operators of c&i energy storage, the selection between air-cooled and liquid-cooled technologies represents a significant technical decision with long-term operational implications. This analysis outlines the functional distinctions between these two prevalent cooling methods.

Principles of Thermal Management and Efficiency

Effective thermal management maintains optimal cell temperature for safety and cycle life. An air-cooled commercial battery storage system uses fans to circulate ambient air across battery modules, offering a mechanically simpler design. Liquid-cooled systems employ a closed-loop fluid to absorb and transfer heat, typically providing superior heat exchange capacity and more uniform temperature distribution within the c&i energy storage unit.

Longevity, Maintenance, and Site Considerations

The cooling approach directly affects system lifespan and operational demands. Liquid cooling’s precise temperature control can reduce cell degradation, potentially extending the service life of the c&i energy storage asset. However, this method introduces more complex components like pumps and coolant, which may require specialized maintenance. Air-cooled designs generally have fewer mechanical parts but can be less effective in environments with high ambient temperatures, affecting the commercial battery storage system performance.

Analyzing Total Cost and Application Fit

Selection depends on specific project parameters. Air-cooled solutions often have a lower initial capital cost and can be suitable for smaller-scale or well-ventilated applications. Liquid-cooled systems, while potentially higher in upfront investment, may offer better energy density and efficiency for high-power, continuous-use scenarios, improving the economics of a large-scale commercial battery storage system over time.

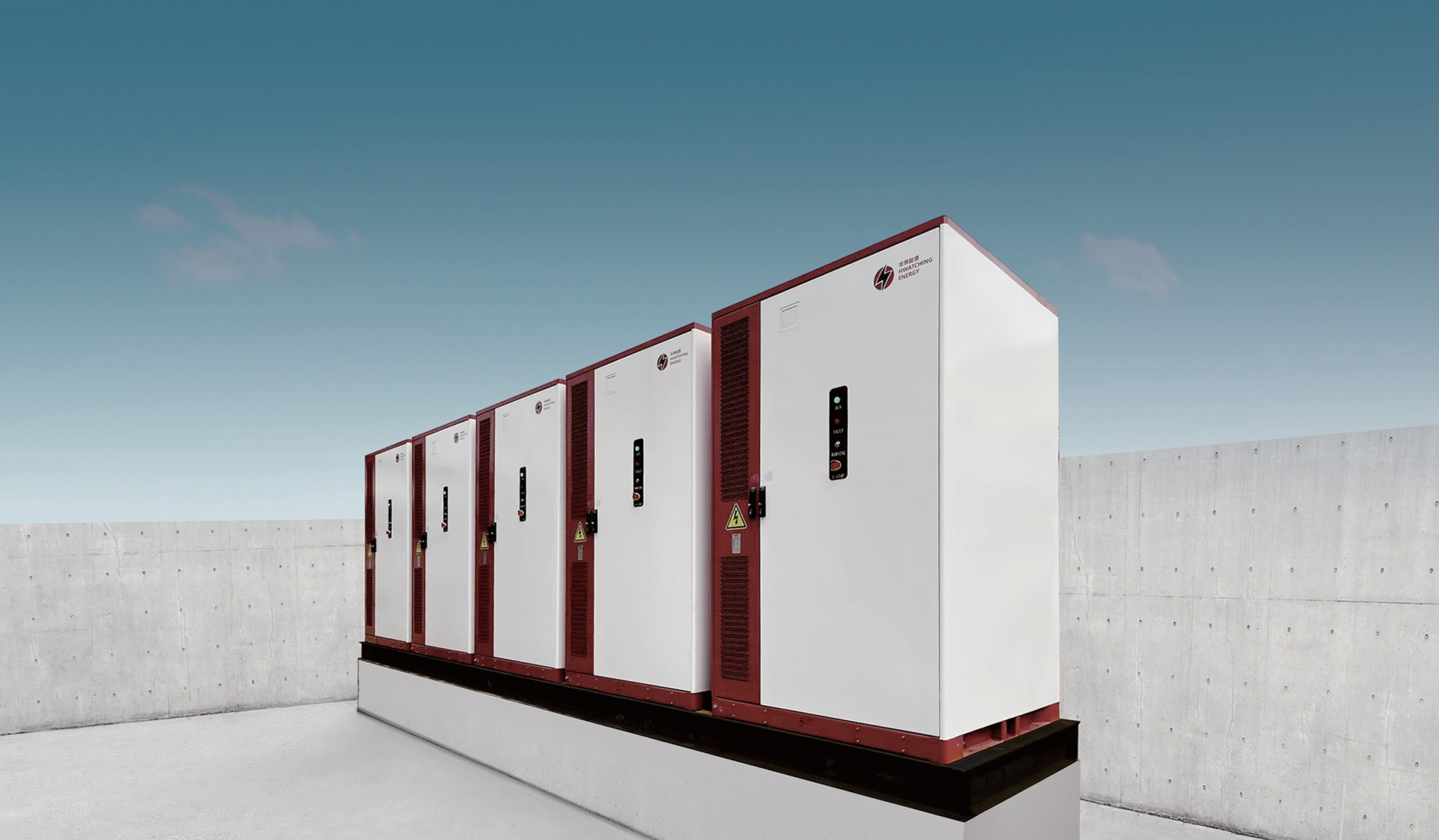

The optimal cooling strategy is not universal but depends on technical requirements and operational goals. Companies like HyperStrong analyze these factors to specify appropriate technology. HyperStrong’s engineering expertise supports clients in selecting a c&i energy storage solution with a thermal management system aligned to their unique site conditions and performance expectations, ensuring a reliable energy asset. Engaging with a specialist such as HyperStrong provides access to informed guidance on this critical design aspect.