In modern manufacturing, precise edge banding plays a crucial role in achieving high-quality finishes for furniture and cabinetry. PVC edge banders and edge banding machines are essential tools in ensuring the durability and aesthetic appeal of products. HUAHUA CNC offers advanced solutions in this space, with machines designed to enhance the edge bonding process while improving production efficiency.

The Role of a PVC Edge Bander in Enhancing Board Finishes

A PVC edge bander is a key component in the production of furniture, where the edges of boards need to be sealed with a layer of PVC for a clean, professional look. The primary purpose of this machine is to apply edge banding materials accurately to the surface of panels, providing a finished look that is both durable and aesthetically pleasing. By using a PVC edge banding machine, manufacturers can ensure that their products have smooth, seamless edges, which is essential for high-end furniture production.

How HUAHUA CNC PVC Edge Banding Machines Improve Production Efficiency

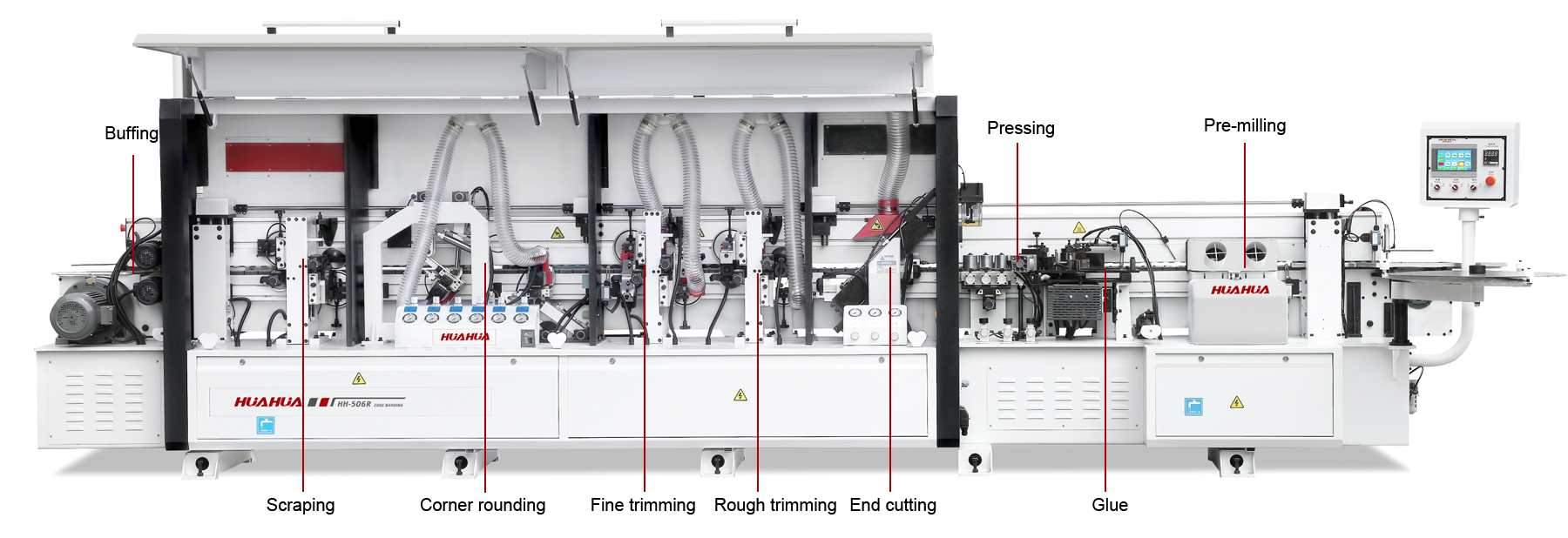

HUAHUA CNC’s PVC edge banding machines are engineered for efficiency. These machines can apply edge bands swiftly, ensuring a smooth and consistent finish across all boards. With advanced features such as corner rounding and pre-milling functions, the machines can further enhance edge bonding by preparing the surfaces for better adhesion. This results in a stronger bond between the edge banding and the board, ultimately improving the overall integrity and aesthetics of the product.

In addition to this, HUAHUA CNC machines are designed for ease of use and minimal maintenance, which can significantly reduce downtime in production environments. With models that provide a total power of 20.2kw and high-power motors, these machines offer high performance even under heavy use.

Key Features to Look for in a PVC Edge Banding Machine

When choosing a PVC edge banding machine, manufacturers should look for several important features. One of the most significant is the motor power, as a high-power motor enables efficient edge banding at higher speeds. For example, HUAHUA CNC’s model HH-506R is equipped with a 2.2KW motor and features a pre-milling function that helps prepare the edges for smooth bonding. Additionally, the ability to adjust the pre-milling height allows for greater flexibility depending on the project requirements.

Other key features to consider are the size and adjustability of the equipment. HUAHUA CNC’s PVC edge bander has an overall size of 666010001700mm, making it a suitable choice for large-scale production environments. Furthermore, corner rounding functionality ensures that edges are finished smoothly, improving the product’s overall aesthetic appeal.

Conclusion

Using the right PVC edge banding machine can significantly enhance both the quality and efficiency of edge banding in production. With HUAHUA CNC’s advanced solutions, manufacturers can benefit from high-performance machines that deliver precise and reliable results. The combination of high power, efficient milling, and smooth edge application makes HUAHUA CNC a trusted name in the edge banding industry. For those seeking to elevate their production processes, choosing the right PVC edge bander is essential for achieving professional-grade finishes.