Since its establishment in 2004, Dekuma has focused on delivering specialized solutions in the field of rubber injection molding. They have dedicated decades of experience to research, development, and manufacturing of machines that meet the precise requirements of industrial applications. Among these, the rubber track molding machine stands out for its adaptability and reliability in producing high-quality rubber tracks used in construction vehicles, agricultural machinery, and specialized engineering equipment.

Specialized Applications of Rubber Track Machines

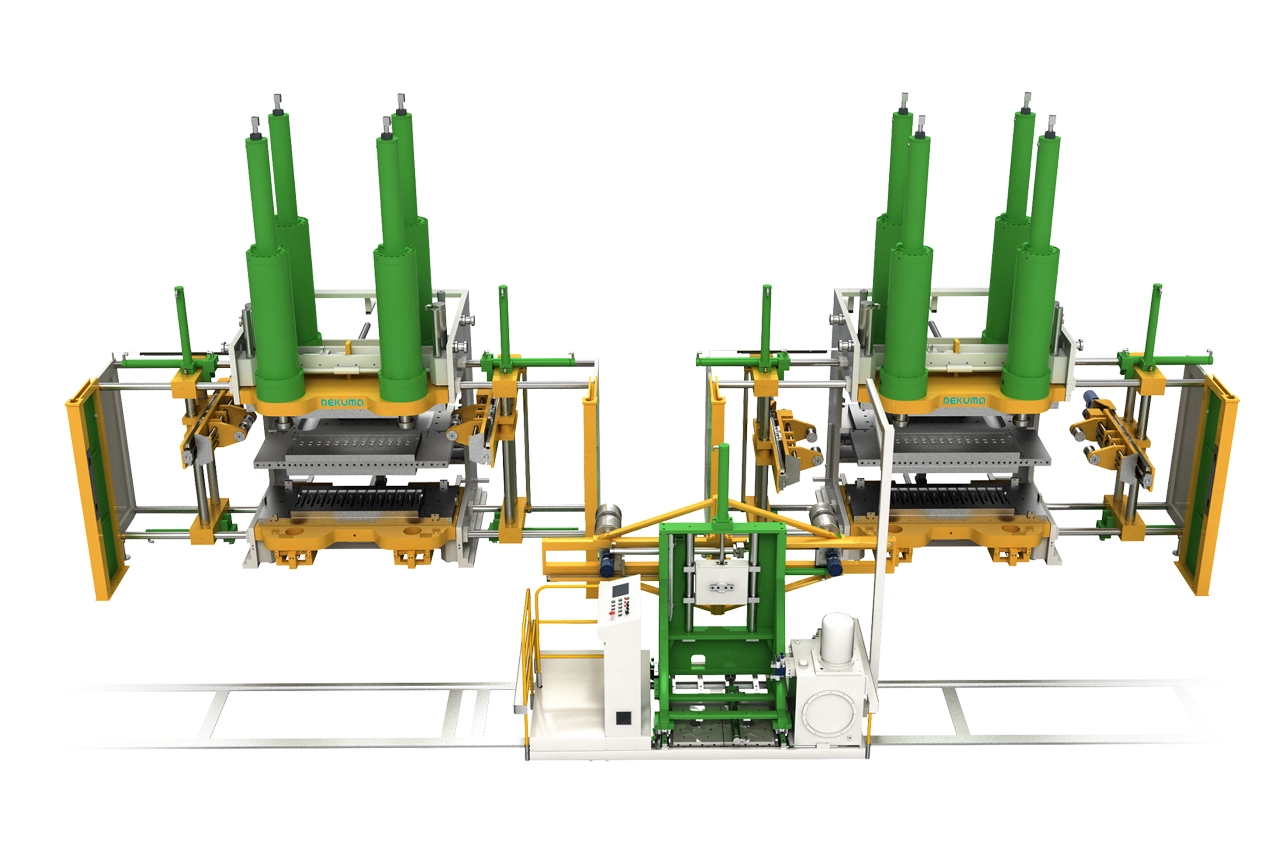

The rubber track machine provided by Dekuma demonstrates particular advantages in producing components such as insulators and rubber tracks for heavy-duty vehicles. These machines are engineered to deliver consistent quality while accommodating the complex shapes and materials required in niche industrial sectors. They have been developed with a focus on precision and efficiency, allowing manufacturers to meet the growing demands of specific markets. By designing core mechanical parts in-house and carefully selecting all materials, they maintain high reliability, which is crucial for safety-critical applications in vehicles and machinery.

Customization and Turnkey Solutions

One of the strengths of Dekuma lies in offering tailored solutions for diverse industrial needs. Their rubber track molding machine can be adapted to specialized production lines, enabling manufacturers to optimize workflow and minimize downtime. They provide full turnkey services that include technical guidance, equipment installation, and ongoing support, ensuring clients can integrate these machines seamlessly into their operations. Over time, they have deepened their expertise in specialized applications, making their machines a suitable alternative to international brands for industries requiring precision and durability.

Conclusion

With a commitment to innovation and customer-centric values, Dekuma continues to enhance the performance and versatility of their rubber track machine and other rubber injection molding equipment. By emphasizing technological reliability and tailored industry solutions, they provide manufacturers with tools that consistently meet demanding standards. Their approach ensures that clients in niche sectors, such as rubber tracks and insulator production, benefit from efficient, high-quality machinery that supports the advancement of the rubber and plastic manufacturing industry.