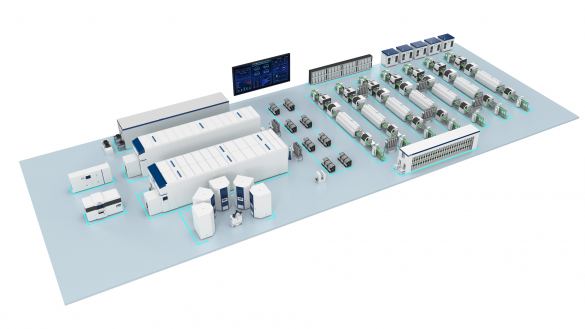

In the fast-paced world of electronics manufacturing, PassionIOT stands out as a leading name among SMT machine manufacturers. Specializing in surface mount technology (SMT), PassionIOT offers innovative solutions that streamline production processes and enhance operational efficiency. With a focus on reducing labor costs and minimizing errors, the company is dedicated to transforming the landscape of SMT production.

Challenges in the SMT Production Line

One of the primary challenges faced by SMT machine manufacturers is the labor-intensive nature of paper document delivery. This process not only increases the risk of errors but also burdens operators with excessive manual tasks. By integrating automated solutions, PassionIOT aims to minimize these labor-intensive activities, allowing operators to focus on more critical tasks that require human oversight.

Additionally, stagnant materials can lead to significant waste in the production line. When materials are not consumed efficiently, this results in inventory challenges and low inventory efficiency. PassionIOT’s innovative systems provide real-time tracking and management of components, ensuring that materials are utilized effectively and reducing waste in the process.

Streamlining Material Delivery

Effective communication between front-end and back-end task operators is crucial for a successful SMT production line. Without a robust communication mechanism, information disconnection can occur, leading to delays and inefficiencies. PassionIOT’s solutions enhance connectivity, allowing for seamless material delivery and improved coordination between teams. This integration not only speeds up the production process but also enhances overall quality.

Conclusion

In conclusion, PassionIOT exemplifies the future of SMT production through its commitment to addressing the challenges faced by SMT machine manufacturers. By focusing on automation and communication, the company is setting new standards in surface mount technology, streamlining operations and paving the way for a more efficient manufacturing landscape.