In modern feed and food engineering, production safety, efficiency, and equipment reliability are top priorities. FAMSUN, a recognized name in the industry, offers advanced solutions to meet these demands. The FAMSUN animal pellet making machine combines high-end design with automation, helping feed producers achieve stable, safe, and efficient operations for pig and poultry feed manufacturing.

Mechanical Advantage for Reliable Feed Quality

FAMSUN’s K Series animal pellet making machine is widely used in processing piglet, fattening pig, and poultry feed. Designed for flexibility, the machine supports various feed formulations and growth-stage requirements. With personalized configurations and precision components, FAMSUN ensures each animal pellet making machine delivers consistent pellet quality while reducing operator error and manual labor risks.

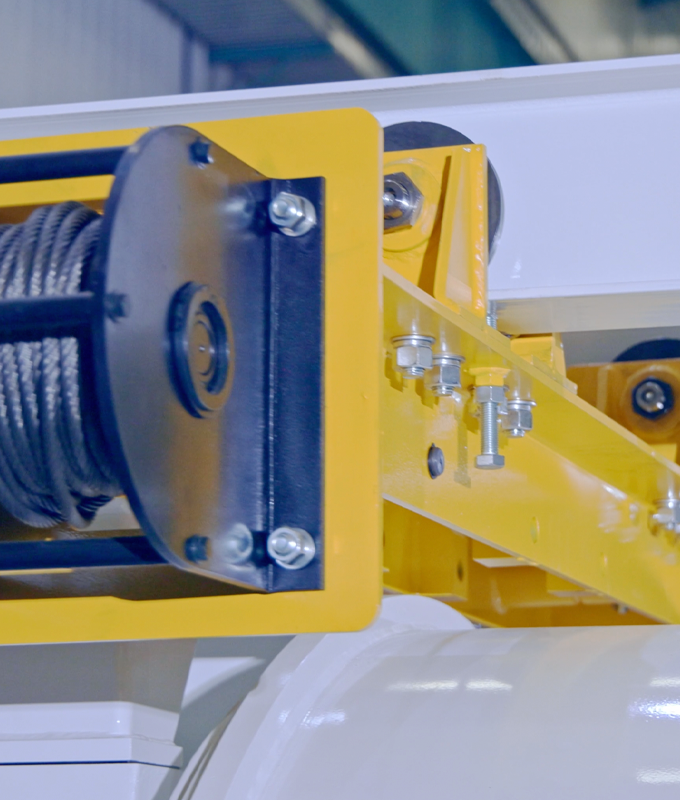

The integration of imported gearboxes and bearings increases structural strength and machine stability. These features reduce vibration and overheating, enhancing safety while supporting continuous, high-load operation.

Safe and Efficient Pellet Processing

Safety monitoring is crucial in food and feed manufacturing. The FAMSUN animal pellet making machine supports compatibility with both standard and thermal conditioners, meeting a wide range of feed safety standards. Automation reduces human contact and improves hygiene, helping manufacturers maintain strict safety compliance throughout production.

Smarter Manufacturing for a Sustainable Future

By adopting the FAMSUN animal pellet making machine, factories benefit from reduced energy consumption, faster production cycles, and lower maintenance downtime. The result is safer, more efficient, and cost-effective feed processing with less reliance on manual labor.

Conclusion

FAMSUN continues to lead in food and feed machinery by delivering dependable animal pellet making machine solutions tailored for today’s industrial demands.